Instructions

for

SCANNING TUNNELING MICROSCOPE

(STM)

By,

Eric Wittinger

Disassembling the STM

-

Open acoustic box

-

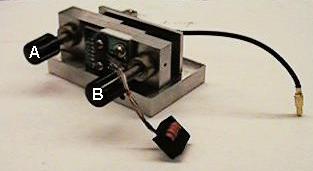

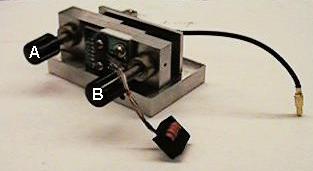

Disconnect the 2 main connectors (plug and coax cable) on STM (Figure

1)

Figure 1. Connectors.

-

Take STM unit our of acoustic box (Figure 2)

Figure 2. STM unit and Acoustic box.

-

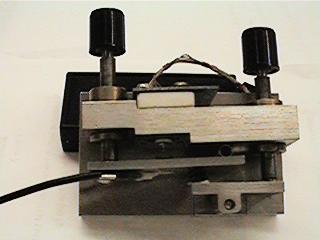

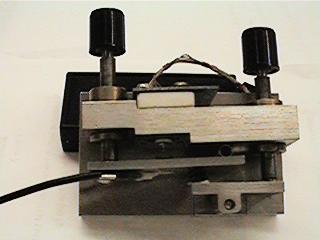

Loosen course positioning screws (2) until sample holder is free. (figure

3)

-

Knob A twists counter clockwise to loosen

-

Knob B twists clock wise to loosen

Figure 3. Positioning Knobs.

-

Remove sample holder from STM Module (Figure 4)

-

Careful not to damage the tip

Figure 4. Sample holder.

Cleaning Sample

1. Supplies needed Scotch Tape.

-

Take a strip of tape and firmly press onto the sample on the sample

holder

-

Carefully remove the tape

-

While removing the tape you want a continuos layer of the sample material

to come off onto the tape.

-

Sometimes this does not occur and jagged flecks of the sample material

are left on the sample surface. These need to be removed with the tape

-

This is done by touching the tape to the sample until those areas are

smooth and one even lay of the sample is exposed

Changing the Tip

-

Remove the Sample plate

-

Remove the tip from the tip holder (Figure 5)

-

Use large magnifying glass with back lighting

-

Use needle fine tipped pliers to grip the tip

Figure 5. Tungsten Tip.

-

Select a new tip

-

Using fine tipped pliers pace ¼ of the tip into the tip holder

-

Slightly bend the tip to one side of the holder

-

Press the another ¼ of the tip into the holder

-

Slightly bend the tip in the opposite direction of step 5

-

Press the tip the rest of the way into the holder.

-

Note: This is done to hold the tip firmly in place.

Reassembling the STM and Adjusting the Tip

-

Carefully place sample holder plate into STM module (Figure 6)

Figure 6. Assembled STM Unit.

-

Using the 2 course adjusting screws roughly adjust the sample holder

to obtain a flat sample plain (See Figure 3)

-

Turn Knob A clockwise to tighten

-

Turn Knob B counterclockwise to tighten

-

Use a light microscope to due fine adjusting of the tip close to the

sample surface

(Figure 7)

-

CAUTION: Do not touch the tip to the sample. This will ruin the tip

-

Use the mirror image scene on the sample and the real image of the tip

as a guide to how close the tip is to the surface

-

Careful not to touch the surface with the tip. This will ruin the tip

Figure 7. Light Microscope.

-

Place the STM module back into the acoustic box on the dampening unit

(Figure 8)

Figure 8. Dampening Unit.

-

Reattach the 2 main connectors (plug and coax cable)

Powering up the up STM

-

Turn on computer

-

Make sure the Isolation Power supply is hooked up to power the STM (Figure

9)

-

NOTE: If the Isolation power supply is not hooked up the image received

by the computer will be contaminated with noise for the standard power

socket

Figure 9. Isolation Power Supply.

-

Turn on the CSTM 9000 Unit I, power switch located on back of unit (Figure

10)

Figure 10. CSTM 9000 Unit.

-

Vbias = approximately 35 mv (Figure 11)

-

Iref = approximately

-0.99 nA (Figure 11)

Figure 11. Vbias, Iref,

Zvoltage.

-

Turn on High Voltage Unit IV, a large

red toggle switch (Figure 12)

Figure 12. High Voltage Toggle.

Setting up Computer Program

-

NOTE: CNTL C will terminate the program

at any time

-

Locate VSCAN1.EXE on the computer

-

Change directories to C:\STM to Find VSCAN1

-

Run this program by typing VSCAN1 at prompt.

C:\STM\VSCAN1

-

Press <ENTER>

-

Main Menu will appear with options (Figure

13)

-

Title Acquisition Program

-

Quite to Menu -- Exits to main

menu

-

Option Topo -- Topographical scan

-

Sts scan -- Do not use this function,

(not operational)

-

Iv curve -- Do not use this function,

(not operational)

-

Move Tip -- Moves the tip

-

Change Para -- Do not use this

function, (not operational)

-

File Para -- Do not use this function,

(not operational)

-

Engrave -- Will make a trench in

the sample with the tip

Fine Adjustments of the STM

-

Use the 2 course adjustment screws to

move the tip close to the sample

-

CAUTION: This is a very sensitive procedure

-

Watch the Zvoltage as this

is done

-

Turn Knob B counter clockwise very slowly

to make the necessary adjustments

-

As Zvoltage approaches zero

volts stop the adjustment

-

The working range for the Zvoltage

= 15 – 0 volts

-

Reseal the acoustic box

-

Let system settle out vibrations for approximately

5 minutes.

To View Sample

-

Select T this will start the computer

scanning the sample

-

The computer screen will automatically

change and start to display the sample scans

-

ESC to return to the main menu

Other Modes of Scanning the sample

-

To change the scanning method flip the

output switch on the CSTM-9000 unit (Figure 13)

Figure 13. Scanning Method Switch.

-

CC – Constant Current Scan

-

CH – Constant Height Scan

Powering Down the STM

-

Quite VSCAN1 program

-

Open up Acoustic box and back the tip

away from the sample surface

-

Use Knob B and turn it clockwise

-

Adjust the tip until Zvoltage

= > +140

-

Turn off the High Voltage switch on the

CSTM-9000

-

Turn off unit I (Power switch is on back

of unit)